2026 Author: Priscilla Miln | miln@babymagazinclub.com. Last modified: 2025-01-22 17:55:18

A distillation column is a specialized device designed to separate liquids with excellent boiling points. Typically, such devices are used for industrial purposes, but sometimes equipment is also made for home use. A distillation column is a rather complex technical apparatus and it is much more difficult to create it than a conventional moonshine construction. However, even at home, this is feasible.

Is it worth doing the production yourself or is it better to buy a machine

It's worth making a do-it-yourself distillation column, although you can also purchase this unit. The columns are available for sale, but not all people have the means to buy. In addition, at home there will always be improvised materials from which it is realistic to create a working structure, and you can enjoy drinks of your own preparation. It is worth noting that a do-it-yourself distillation column will cost you two to three times cheaper than a purchased home-made distillery.

Things to remember when creating a column

A distillation column is one of the necessary parts of all modern installations that are designed to separate liquids with different boiling points. The devices are often used for industrial and domestic purposes. It is quite possible to create an apparatus with your own hands, the main thing is to understand the principle of operation of the device and stock up on all the necessary details. Before studying the operation of a distillation column, it is worth learning the principles of rectification and distillation.

More about rectification and distillation

First, let's talk about distillation. Alcohol and other vapors will be separated in the hot wash as the mixture warms up, then they are mixed in the upper part of the cube and, in fact, are discharged together through the tube to the refrigerator and reservoir. It is worth saying that it is difficult to separate vapors into useful ones (alcohol itself) and into harmful ones (this is referred to as "fuel oil"), and it is temperature control and the separation of the so-called "heads" and "tails" that help to partially achieve good results.

Now let's talk about rectification. Vapors will rise up not directly, but passing through a special liquid called reflux. The phlegm is located in "plates" that are installed in the column of the mini-distillery. In this liquid, volatile components will settle, which boil very easily at low temperatures, and hardly volatile substances remain in the vapor. As a result, vapors purified from heavy fractions will rise upwards. It's a pity, but flavoring components are also classified as non-volatile components.

Peopleboth types of mash distillation are used. Some people like distillation more, while others prefer rectification. What to choose is up to you. An ordinary home-made moonshine with a prybnik will not give the purest alcohol, but it still meets all accepted standards, and the drink turns out to be very tasty.

What are the advantages and disadvantages of distillation systems

Distillation has the following benefits:

- forcing speed is very fast;

- devices with this distillation system cost less;

- with repeated filtration and distillation, the quality of alcohol will comply with all GOST standards;

- the taste of the drink will have shades of the raw materials from which alcohol is created.

What are the disadvantages of distillation? There is only one drawback - to obtain pure and strong alcohol, chemical dehydration will be required.

Rectification has the following advantages:

- during distillation, a very pure product is obtained, and for moonshine distillate, such success is extremely difficult to achieve;

- it is possible to immediately produce high-strength alcohol.

Rectification also has disadvantages:

- the distillation process takes a long time;

- understanding all the nuances of the process is rather difficult;

- the device is not cheap;

- you will need to spend money on water and heating the device.

Before choosing one or another method, you should carefully weigh everything. However, rectificate has more beneficial sides than distillate. Now you can figure out how to make a distillation column in a variety of ways.

Raw material base for creating a column

To create a device, you will need to stock up on the following materials:

- Stainless steel pipe, which has the following parameters: a diameter of thirty-five to fifty-five millimeters, a length of one hundred and twenty to one hundred and fifty centimeters, and a wall thickness of one millimeter.

- Heater for the manufacture of a heat-insulating layer in some parts of the apparatus.

- Thermos to create a dephlegmator, the volume of the thermos should be up to a liter.

- Part of sheet metal made of the same material as the pipe.

- A piece of PTFE or its substitute for making a thermometer sleeve.

- Gas burner.

- Faucet adapters.

- Drill with drills of various diameters.

- Adapters for joining the pipe of the device and the dephlegmator with a distillation cube.

- Emery nozzle for a drill or machine.

- Tubes with a diameter of four to six millimeters will be used to create outlets for water and a refrigerator.

- Thermometer.

- Hammer, file, pliers, sandpaper.

- Solder and flux.

- A soldering iron with a power greater than 100 watts.

- Tube or good hose, ten centimeters long.

When you have prepared all the materials, you can view the drawing of the distillation column and start making it.

Production of a thermos column

Now you can start creating the device:

- Cut off the required length of pipe (titanium is ideal), chamfer and trim the edges.

- Now we are starting to create an adapter that will fix the distillate selection units and the tube with the apparatus cover into a single structure. The adapter must be firmly inserted into the pipe on one side, and on the other side it must have a thread of almost two millimeters.

- Now for the distillation column, you will need to make support washers for nozzles, the diameter of which should be such that they can be tightly planted in the pipe. Usually the diameter will be three to four millimeters. On one side of the adapter, you will need to insert a pipe, and an adapter will be soldered at the junction with the cube.

- Now place a tinned adapter into the pipe, and heat the soldering area with a burner.

- Home distillation column needs more filler. Pour it into the pipe, then shake the pipe strongly so that the filler is evenly distributed over it. It is important that the pipe is filled to the top with filler.

- Now you will need to insert a support washer for the nozzle into the pipe, then install the end of the selection, solder, and additionally heat this area with a burner. Now apply a heat insulator on the pipe, and it should be along the entire length.

- Disassemble the thermos, clean the bottom with sandpaper, and then carry out another tinning. From the tin, create a bracket, and from the wire, create loops that are inserted into the hole of the bracket and twisted with pliers.

- Pinch the free end of the wire in a vise, then attach it to the wall of the thermos, and after the thermos you need to shake it sharply and make sure that the bottom completely falls off.

- It is best to grind the connecting seam until a small gap appears between the lid and the flask itself. You will need to pull out the inner flask from the outer flask.

- Now let's start creating a dephlegmator. To do this, you will need to remove the bottom and the vacuum cover. Drill a hole in the inner flask in the central zone to let air in. Clean and tin the hole area, and then insert the tube and seal it in the hole. Make another hole in the center of the bottom of the thermos and put a flask on the bottom of the device, solder the tube and the bottom of the thermos.

- The drawing of the distillation column assumes that the neck of the thermos and the place where the distillate is taken will need to be tinned. The knot will need to be inserted into the neck, and then solder it. A drill will help you make holes for the tubes in the upper and lower parts of the outer flask, this is necessary for the supply and removal of cold water. Now insert the tubes into the holes you need, and carefully solder the joints. Drill another hole in the place where the distillate is taken, which is necessary for the thermometer sleeve. In the sleeve, also drill the desired hole for the thermometer probe (a couple of millimeters is enough). Now insert bushing and selection.

- At the end, the moonshine distillation column in all places of adhesions will need to be washed with soda solution. After that, you can screw the reflux condenser to the column and rinse everything againsolution. That's it.

Homemade devices are often better and more efficient than purchased ones, but if you do not want to do everything yourself, then you can purchase the device.

What is the working principle of distillation column

So, the mash will need to be poured into a cube, which is gradually warmed up. As a result, steam will be released, which contains alcohol. The vapor is much lighter than the liquid and will rise to the top of the column. There is also a reflux condenser, which is cooled by cold water. As a result, the steam begins to condense and starts to flow down, but on the way it will still get on the special components of the best distillation column.

At this time, the mash is already continuing to boil, and vapors will constantly flow into the upper part, and they will begin to mix with condensate. This ongoing process is called rectification. As a result of rectification, a condensate called phlegm will be created, and it will be saturated with vapor, and the steam, in turn, will be saturated with phlegm. Such an exchange will create a mixture of vapors, of which the lightest particles will rise to the top, and they will contain the largest concentration of alcohol. Its boiling point will be lower than that of water. In the upper part of the column, vapors with alcohol go to the reflux condenser, where they are filtered and saturated, and then to the refrigerator. This is how pure alcohol is made.

Do you think that the best distillation column is purchased? No, you are wrong about this. With your own hands you can make an excellent distillation column for alcohol and it haswill have the same properties as the factory device, the main thing is to adhere to all the nuances when creating.

Choosing a refrigerator in action is the most important part

The refrigerator plays an important role in the process, so its choice will need to be taken with special care.

Remember! Using the Dimroth refrigerator is impractical. This is due to the fact that the design is different in that components with a low boiling point can penetrate into the cooling zone. This refrigerator is good for those mixtures that boil at temperatures above one hundred and sixty degrees.

Don't use an air cooler, all because the cooling will be extremely inefficient. It can be effective if a dry steamer is added to the column, but it is absolutely not needed there.

The best option is a glass lab cooler. With such a refrigerator, you will receive a high-quality moonshine still with a distillation column. Where can I get such a cooler? It is sold in any store with laboratory utensils. If you still want to control the rate of product selection, then the dephlegmator tube connected to the refrigerator can be equipped with an additional tap.

Features of the device and its verification

Each apparatus with a distillation column has its own assembly features, and it must be checked before use. The first thing to note is that all elements in the structure must be connected by ordinary soldering. For the cooler, always choose a conventional flow throughwater. Some factory models still use a boiler.

It is worth saying that small deviations in the calculation of the distillation column and assembly will not lead to a deterioration in the quality of the product at the end. So you don't have to worry about this issue. However, if you want to increase the volume of alcohol produced at the outlet, you will need to double the size of the distillation column. For example, if you use a one and a half meter pipe for a column, then you can get up to thirty liters of alcohol every day. Accordingly, an increase in the pipe will lead to large volumes of alcohol. At the end of the operation of the apparatus, it will be necessary to lubricate all its connections with soapy water, and then blow it. This is how you can also see unnecessary leaks, because soap bubbles will appear. If you have connected a water cooler to the water supply pipe, you will be able to detect leaks in the system, but under pressure.

Some tips for making mash

The following are recommendations from experienced alcohol masters:

- You shouldn't put extra yeast, because it will lead to the formation of fusel oils.

- It is best to clean the resulting alcohol with a solution of potassium permanganate. You will need one or two grams of the product per liter, but first dilute the potassium permanganate in boiled water. Then stir and wait until the precipitate falls out (this will last about ten hours), and after that the alcohol will need to be filtered, and this can be done through cotton wool.

- Column will give the best resultsnot immediately, but after a while, when you learn how to use it correctly and learn the different nuances of creating high-quality alcohol at home.

What gives the column as a result

If you use conventional distillation, then you will get insufficiently purified alcohol at the output, although it will comply with GOST standards. The column will give you much better results due to its properties and cleaning capabilities. Yes, factory columns are quite expensive, so it’s better to make the device yourself. You can make the device yourself without much effort, if you follow the instructions, you will have at hand the necessary materials and free time to create a unique device.

Thanks to the distillation column, you can get very pure alcohol, which is used in virtually all areas of activity. For the holidays, you will no longer need to buy alcoholic beverages in stores that are not distinguished by their cleanliness, moreover, there are still fakes, and this is extremely dangerous for he alth. Surrogate alcohol can lead to disastrous consequences, even death, so it is better to use homemade alcoholic drinks. You will be 100% sure of your product and its purity.

Every person will be able to create a distillation column for a moonshine if they make enough efforts for this business and allocate time for it. Do you want to succeed in the alcohol business? Everything is in your hands, just try it.

Recommended:

Five-point seat belt: device, fastening, principle of operation, purpose

One of the main criteria for choosing children's products is safety. It is important to remember this on the road, on a walk with a stroller, and even seating the child in a high chair. It is necessary to carefully approach the choice of means of protecting the child. Why should you pay attention to the five-point seat belt? If only because even in sports cars this driver protection is installed. After all, such belts allow you to evenly distribute the load when tensioned

Door closer: principle of operation, device and installation recommendations

If it becomes necessary for the door to close automatically, the best thing you can think of is to install a door closer. Adjustment and proper installation of this device will solve the problem of drafts once and for all, as well as overcome the laziness and forgetfulness of some visitors

Diagnostic scales: overview, features, types and principle of operation

Despite the low demand, floor diagnostic scales deserve attention. Those people who want to lose weight will not be able to do without them. Ordinary devices will only be able to display a person’s weight, and a “smart” device will even calculate how many percent of fat mass has gone during the diet. So, let's figure out how these scales work, get acquainted with their range, and also study user reviews

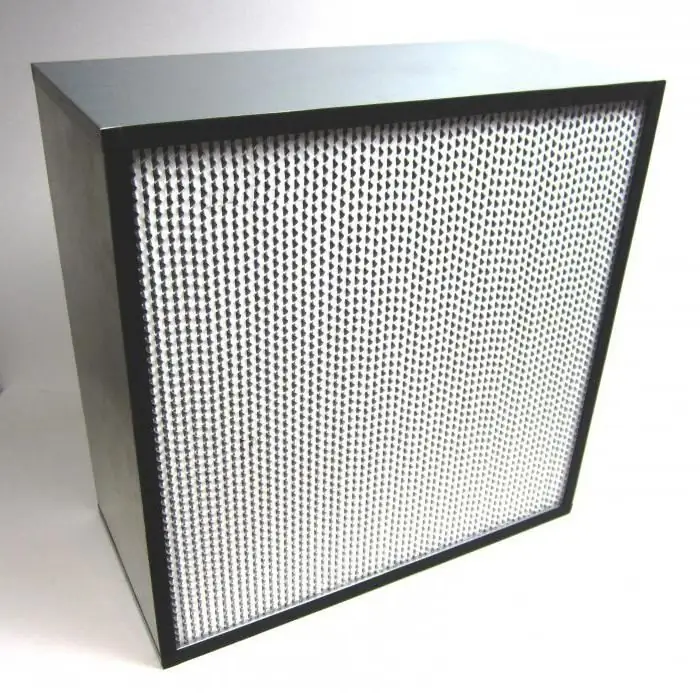

HEPA filter "Folter", filters for vacuum cleaners, cellular and cartridge: principle of operation, design features

One of the main elements of ventilation systems in residential premises, production workshops and many types of equipment are filters, the variety of designs of which is explained by various cleaning methods and types of pollutants

Door lock from children: description, device, principle of operation, application, photos and reviews

About 7-8 months of life, the activity of the baby becomes most active. The child is constantly exploring every corner of his home, trying to open drawers, doors. And during this period, parents will come to the aid of special door locks from children, which can be purchased at almost any children's goods store