2026 Author: Priscilla Miln | miln@babymagazinclub.com. Last modified: 2025-01-22 17:55:26

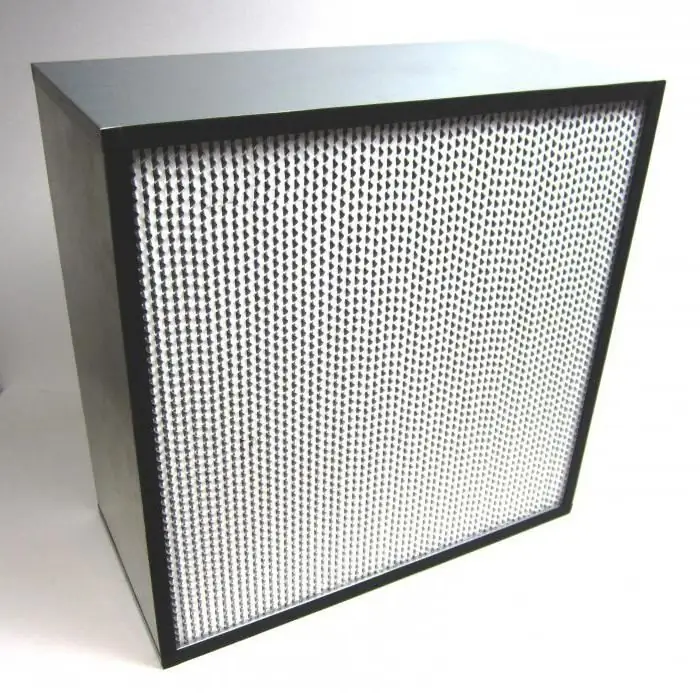

One of the main elements of ventilation systems in residential premises, production workshops and many types of equipment are filters, the variety of designs of which is explained by various cleaning methods and types of pollutants. The Folter HEPA filter is one example of a widely used cleaning equipment manufactured by a domestic enterprise that has been making air filters and dust collectors for over 60 years.

Folter Filters

Research and production company "Folter" was registered on the basis of the laboratory of the Institute of Central Research Institute of Industrial Buildings in 1995.

HEPA-filter "Folter" is the final stage of air filtration in clean rooms of production shops, medical institutions, in pharmacy, electronics, food industry.

Types of HEPA filters: FyaS, more powerful FyaS-MP. Can be installed in MV air distribution models for final air purification in rooms or in SSF sections, for purification of large volumes of air.

Cell filters from "Folter" FyaS

FyaS-type filters have a cellular folded design.

Purpose: final air purification with a sterilizing effect. They are installed in medical institutions or in workshops that produce medicines, laboratories or other rooms that require a high level of air purification.

HEPA filter "Folter" FyaS consists of:

- Case.

- Filter material that is folded into the housing.

- Foil (aluminum) separators are placed between the filter media to prevent it from sticking together.

- Instead of foil, special threads can be used that stick to the material.

Material for the case is:

- Aluminum profile. Filter depth 78, 150, 300 mm.

- Stainless steel sheet or MDF.

After installing the filter material in the housing together with threads or mesh, it is filled with sealants along the edges. The housing forms a pressing surface with a thickness of:

- aluminum- 15mm;

- MDF - 12mm;

- stainless steel - 18 mm.

Rubber is glued on top and a decorative distribution grille is installed.

Filter classes FyaS: E 10, E11, E12, E13, E14, efficiency increases with class height from 85 to 99, 995%.

HEPA filter "Folter" FyaS-MP - cell pleated, with special mini-pleated packages FyaS-MP, designed to process large volumes of polluted air with a high filtration rate. Unlike FyaS, suitable forinstallation directly into the duct of an existing ventilation system.

Adjustments for filtering air in vacuum cleaners

Vacuum cleaner filters are household filter elements, which are the last barrier before air from the vacuum cleaner body gets back into the living space. Almost all modern models practice the use of one of two types of filter systems:

- HEPA filter - stands for "High Efficient Dust Retrieval" In addition to the main HEPA filter, conventional foam padding filter elements are usually installed in vacuum cleaners.

- Water filter.

HEPA filters for vacuum cleaners can be of two types:

- Disposable paper combined with fiberglass.

- Reusable, consisting of PTFE.

Most often in vacuum cleaners use disposable models of small sizes. They quickly become clogged with debris and reduce the performance of the vacuum cleaner, increasing engine overheating.

The filter is designed for a delay of 0.1 to 1.0 µm. For NERO filters, the ingress of particles above the norm is highly undesirable, as they accelerate its clogging and reduce efficiency.

Types of water filters:

- Turbulent. The most common simple type. With air, dust and debris enters the container with water, where it remains. The disadvantage is the incomplete suction of dust and the installation of additional filter elements.

- Separator type. Dust with air enters the water, in which the separator is located.mechanism, and the dust is reliably drawn into the water and does not scatter. More expensive model.

Cartridge filters: types and features

Can be produced for both water and air purification.

Water filters - flow or flask - are used both in everyday life to purify water for drinking or swimming pools, and in production conditions.

The selection criterion is the volume of water throughput per hour and the degree of purification.

The degree of cleaning depends on the porosity of replaceable cartridges from 0.5 to 100 microns. Cleaning is not provided, only replacement.

Cartridge pleated dust filter is designed to separate dust particles from gas. The gas enters through the cartridge and exits through the internal port already cleaned.

Conclusion

The role of filter elements in modern human life is difficult to overestimate. During operation, it is necessary to remember the standard rule: a dirty and clogged filter can become an even greater source of pollution than the medium passing through it. Timely cleaning and replacement is a guarantee of obtaining a quality result guaranteed by the manufacturer.

Recommended:

Electrolux vacuum cleaners: an overview of the best models and reviews about them

It's deceiving that choosing a vacuum cleaner is a simple matter. In fact, you need to analyze many factors: your needs, your budget, the market for the offered copies and determine the moments that are critical for yourself

DIY distillation column: device, features and principle of operation

Distillation columns are necessary devices in many moonshine devices. If you want to get high-quality alcohol, then this device is vital for you. Let's deal with it in more detail

Quality and affordability of Thomas Twin TT vacuum cleaners

Why choose a Thomas Twin TT vacuum cleaner? Because it is the leader of sales in the Russian market. With its low cost, it has the best qualities, meets all consumer needs for both wet and dry cleaning

Diagnostic scales: overview, features, types and principle of operation

Despite the low demand, floor diagnostic scales deserve attention. Those people who want to lose weight will not be able to do without them. Ordinary devices will only be able to display a person’s weight, and a “smart” device will even calculate how many percent of fat mass has gone during the diet. So, let's figure out how these scales work, get acquainted with their range, and also study user reviews

Solar batteries for charging a car battery: the principle of operation, features, manufacturers and expert recommendations

Solar batteries for charging car batteries are becoming more and more popular in our country. They are purchased by car owners both for fully charging the battery and for emergency resuscitation, if necessary