2026 Author: Priscilla Miln | miln@babymagazinclub.com. Last modified: 2025-01-22 17:55:27

Every day we use ballpoint pens, there are printers on the desktops that work almost non-stop. We are already so used to it that we do not think about how it works. And the first step towards the invention of all these convenient devices was the recipe for an amazing composition that can leave permanent marks on paper and fabric. However, today we want to talk about what ink is made of. A brief excursion into history and modern technologies will be interesting for adults and children.

Vintage tomes

The thinnest parchment, lines printed on dressed leather, ancient manuscripts always amaze with the fact that you can still easily make out what is written. The first ink was made very simply - they mixed soot with something sticky. It was essentially mascara that dried out and cracked. In addition, it was quite viscous, you had to get the hang of it to bring out a beautiful line. Then the recipe was strictly classified. What ink is made of, only the clergy knew. By the way, there were many variations. They took honey as a base and added gold to it.powder. The composition of elderberries and walnuts was widely used. But all this has already sunk into oblivion. Today, the production of ink has become simple and affordable. Let's follow the chain further.

Nut gall ink

Continuing to consider what ink is made of, one cannot forget the famous discovery, namely, special growths on oak leaves. They are called galls, and insect larvae live in them - nutcrackers. That is why the growths are called ink nuts. Juice was squeezed out of them, then it was mixed with iron sulfate and glue was added. It turned out to be a durable composition with a beautiful sheen. Even today, the surviving manuscripts look very fresh. However, there was one important nuance. This ink was colorless and could only be read when the letters dried.

Revolution in history

In the 19th century, people became more educated, many already knew what ink was made of. In 1885 another coup took place. The teacher invented alizarin ink. They were also gallic, but they had an intense color due to a unique additive. Blue-green in the bottle, they turn black when applied to paper. This was achieved by adding krappa, that is, an extract from the roots of madder.

Now the technological revolution was in full swing, and they already learned how to replace crappa with artificial dyes, and ink nuts with gallic acid. But progress didn't stop there. The easiest way to produce aniline ink was found, that is, to obtain synthetic ink diluted in water.dye. With the help of this technology, it became possible to synthesize compositions of various shades. However, it remains a mystery how the ancient monks made the inscriptions with ruby, mother-of-pearl and sapphire ink. These compositions are still known in some monasteries, but this art has never left their walls.

From Antiquity to Modernity

Since ink is made today on a huge, industrial scale, it is easy to guess that humanity no longer turns to nature. Now all produced compositions can be divided into several types. The first group remains the most popular, cheap and simple. This is essentially the manufacture of ink from gallic acid.

The second option is to get the composition using tannin. It is found commercially in the form of a yellowish powder. Glycerin and gelatin are used as thickeners. This way you can make a small amount of ink that will be relatively safe even if accidentally ingested. Of course, this is best avoided.

How to make them yourself

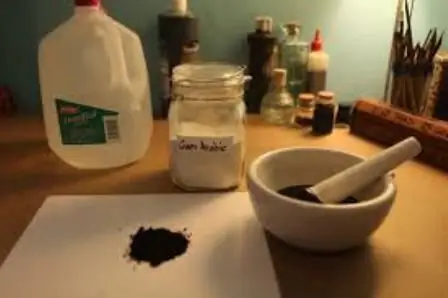

If you really want to try yourself as a medieval monk, then we will tell you how to make ink with your own hands. All components are quite simple. You will need to collect three grams of ink nuts, two grams of iron sulfate and the same amount of gum arabic. Ink galls must be crushed into powder and poured into a vessel. Pour 30 ml of water into it. Pour the same amount of water into another vessel and add all the restComponents. After two days, you can mix both liquids, mix and leave for another 48 hours, then strain. However, you still need to learn how to write with this composition. But since it is quite difficult to make real ink with your own hands, you will have to be content with something that is very reminiscent of them.

Alizarin ink

They are also prepared from ink nuts, but they are distinguished by the fact that they include vinegar. For cooking, you need to take 10 g of ink nuts, 6 g of copper sulfate, 1 g of gum arabic, 100 ml of vinegar. Cooking will take a long time, so immediately tune in to a long process. Crushed galls insist in vinegar for at least 6 days. The remaining components are separately dissolved in acid. On the fifth day, you need to boil the second composition.

After both solutions are ready, you need to merge them together. Now shake the mixture vigorously. The process is almost complete. Wood-acetic acid is the best solvent. Alizarin ink has a big drawback - it does not flow around the pen evenly, but remains on it in a thick mass.

Many options

Today, ink making is an important industry that is only picking up pace. In Russia, they were prepared from iron sulfate, which was added to a decoction of oak nuts. Today, conventional ballpoint ink is a mixture of 50 or more components. Black color is achieved through dyes, but the most popular are triphenylmethane, copper phthalocyanine, they givea blue hue so popular in modern writing.

The production of ink is not complete without ferrous sulfate and tannic acids. Dyes and additives must be mixed with a solvent, they are necessary to make the formula more stable. Synthetic polymers are needed to help regulate surface tension.

Coloring glass

Ink for a smooth surface is prepared from two working solutions. The first is 100 ml of water and 1 g of potassium sulfide and 7 g of sodium sulfide dissolved in it. Prepared by simple mixing. The second contains similarly 100 g of water, 3 g of zinc chloride and 13 ml of hydrochloric acid. The mixture can be used immediately as an ink. You can safely apply on glass and get matte inscriptions after drying.

Compounds for metal

It is possible to call them ink only conditionally. Writing on metal should be done with a mixture of nitric and hydrochloric acid. To do this, the surface is covered with wax, then the inscription is made with a sharp object, and then the composition is applied on top. After five minutes, you can lower the vessel into warm water. To get an analogue of the blue ink inscription, you need to prepare a different composition.

It is prepared by mixing 3.5 g of borax with 15 ml of ethyl alcohol, 2 g of rosin powder and 25 ml of methylene blue solution. The result is a blue inscription.

Fabric ink

We have already reviewed the compositions and are guided by what the ink is made of. However, all these compositions do not have a largeresistance to washing and repeated boiling. To do this, you need to slightly change the recipe. To do this, 42 g of aniline and 2.5 g of Bertolet s alt and 13 ml of water are heated in a flask. Then add 15 ml of hydrochloric acid (25%) and continue to heat the mixture until it darkens. It remains a small matter. Copper chloride is poured into the flask, this process can be considered almost complete.

The resulting solution is heated to a red-violet color. After that, under the influence of a dye, an oxidizing agent and a reaction catalyst, we can get the final result. The ink made according to this recipe is very resistant. They do not fade in the washing process and can be used in light industry.

Instead of a conclusion

As you can see, there are quite a few ways to prepare ink. Modern industry allows you to produce from black to multi-colored ink. Recently, technology has been developed to prevent the appearance of mold. There are special compounds that, when added to ink, completely neutralize the role of the fungus. These are creosote and formalin, salicylic acid.

As you can see, the composition of the ink is not complicated at all. If you are fond of chemistry, then you can easily repeat this at home. However, the big question is whether it's worth the time, especially given the cost of the product in the office supply store and its consumption.

Recommended:

Rinsing the nose with saline for babies: step by step instructions, indications for carrying out and recommendations from doctors

In the nose of the baby, mucus very often accumulates, which makes it difficult for the baby to breathe. That is why it is very important to help the baby in a timely manner. Flushing with saline is a safe and effective way to get rid of mucus and bugs

How to pull out a booger from a newborn: step by step instructions and recommendations

New parents have a lot of questions. These are the nuances of feeding and hygiene of the baby. Including parents are interested in how to pull boogers out of the nose of a newborn, which of the existing methods are the most effective

Exercise for newborns: benefits, doctors' recommendations and step-by-step instructions with photos

Despite the fact that in the neonatal period, the periods of wakefulness are quite short, this time can be used to good use. For the full development of the baby, doctors recommend introducing exercises for newborns from the first days of his life. We will talk about the methods and benefits of gymnastics for the smallest in this article

How to reflash a doll's hair: a master class, step by step instructions and recommendations

Sometimes it happens that your favorite doll, which seems to be still good in appearance, is rapidly going bald from time or someone else's efforts. Is that what happened to your favorite? Doll curls fell off and can not be combed? No problem. Everything can be fixed. In this article we will talk about how to flash the hair of a doll. The master class for this type of repair is quite simple. You will need not so much skills as perseverance and patience. So let's start

How to dry flowers correctly? Step by step instructions, recommendations and features

Flowers are a creation of nature, and ikebana made from dried flowers is a creation of human hands. Before drying flowers, it is important to follow a few simple rules so that the end result will please